Metalworking Lathe & Mill

Operation & Safety

An estimated 3,400 operators of metal-working lathes suffer lost-time injuries annually in the United States.

Some of these are fatal.

Some of these are fatal.

|

April 13, 2011

A Yale undergraduate majoring in astronomy and physics, Michele Dufault, 22, was killed when her hair became caught in the lathe, whose rotating axis is used to hold materials like wood or metal being shaped.Connecticut’s chief medical examiner ruled the death an accident, citing the cause as asphyxia due to neck compression. |

Feb. 17, 2021

A 52-year-old machinist at a manufacturing company was preparing to spot drill the center of a 103-inch piece of round steel in a manual lathe. Because of the length of the steel, 24 inches of the material was protruding out of the back of the unguarded lathe, held in place with an aftermarket clamping device that rotates as the lathe rotates. Security footage showed that while the lathe was in operation and the steel rod was spinning, the machinist attempted to grab a glove from the top of the lathe. The sleeve of his shirt became entangled on the clamping device, pulling him into the lathe between the motor and rotating piece of steel. As the lathe continued to turn, the machinist’s body rotated around the piece of steel and struck the motor about 12 times. An employee in the changing room heard the event, ran out to investigate, shut down the machine and called emergency medical services. First responders transported the partially conscious machinist to a hospital, where he was pronounced dead on arrival. Cause of death was listed as traumatic blunt force injuries. |

June 13, 2017

Machinist Dies After Being Pulled Into Engine Lathe A 57-year-old male machinist died after being pulled into the engine lathe he was operating. The incident occurred in a small commercial metal machining facility in northern New Jersey. On the day of the incident, the victim was filing a 36-inch long, two-inch diameter, high-nickel, stainless-steel alloy rod on an engine lathe. With the chuck rotating, the victim was using a metal file to smooth out portions of the bar when the sleeve of his sweater became caught in the jaws of the chuck. He was pulled up into the lathe and sustained traumatic blunt impact injuries to his left arm and head. The victim died instantly, and was pronounced dead at the scene. Contributing Factors: • Victim wearing a long-sleeved, loose-fitting sweater • Working in close proximity to rotating chuck |

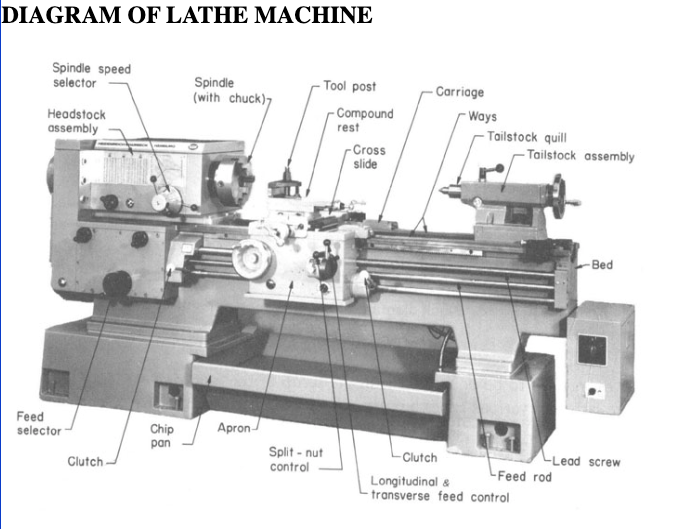

Metalworking Machines - Lathe Machines

Minimum Required PPE

- Safety Glasses

- Closed-toe Shoes

Hazards & Controls

- Lathes contain several fast-rotating parts that can cause contact and entanglement hazards. Keep all body parts away from all rotating parts. Never wear loose-fitting clothing or jewelry while operating a lathe. Tie back and contain all long hair. Use guards to protect from accidental contact with rotating parts.

- When the lathe spindle is set at too fast of an RPM, it will take longer for the spindle to stop rotating in an emergency situation. Limit spindle to 1000 RPM and use the lowest RPM applicable to the task.

- Rotating and other moving parts can create pinch points. Pinch points can crush, bruise, lacerate, or amputate body parts. Utilize guards and avoid contact with these points.

- Cutting Tools, drill bits, machined edges, chips, and cutoffs are potential cut and laceration hazards. Handle all sharp parts and tools with care. Do not clear chips with bare hands. Use a brush or compressed air (< 30psi).

- There are several flying object hazards that can potentially come from a lathe. Make sure to secure both the workpiece and cutting tool. Be sure to remove the chuck key from the chuck. Make sure to keep the work area clean from all debris, chips, and tools.

- High-speed metalworking can create burn hazards from the high amount of friction. Cutting chips, workpieces, and cutoffs can be hot to the touch during and immediately after the work process. Allow enough time for all objects to cool before handling them.

Limitations

- Machining of unusual or exotic materials can create new hazards depending on material composition. Only machine these materials under the supervision of a trained professional. Consult with the applicable Safety Data Sheets to learn more about specific material hazards.

Machine GuardingChuck GuardWorkpiece Guard

Chuck Guard: Protects user from accidental contact with the rotating chuck, helping to eliminate hazards such as pinch point, crushing, and entanglement.

Workpiece Guard: Protects user from the rotating workpiece, helping to eliminate hazards such as crushing, pinch point, burning, and entanglement. This guard also protects users from flying projectiles and chips.

Other Precautions

Emergency Stop buttons should be located at easy to access locations on the machine. The purpose of these buttons is so the operator can stop the machine quickly in case of failure or an emergency situation such as becoming entangled in the machine. These buttons are typically located near the controls of operation.

- Never come near a rotating workpiece for reasons such as cleaning chips or measuring the workpiece. If you need to measure or clean the workpiece, stop the machine and wait for it to come to a full stop.

- If working on a heavy or awkward piece, use another person or some sort of lifting device to help lift and secure the workpiece.

|

|

|

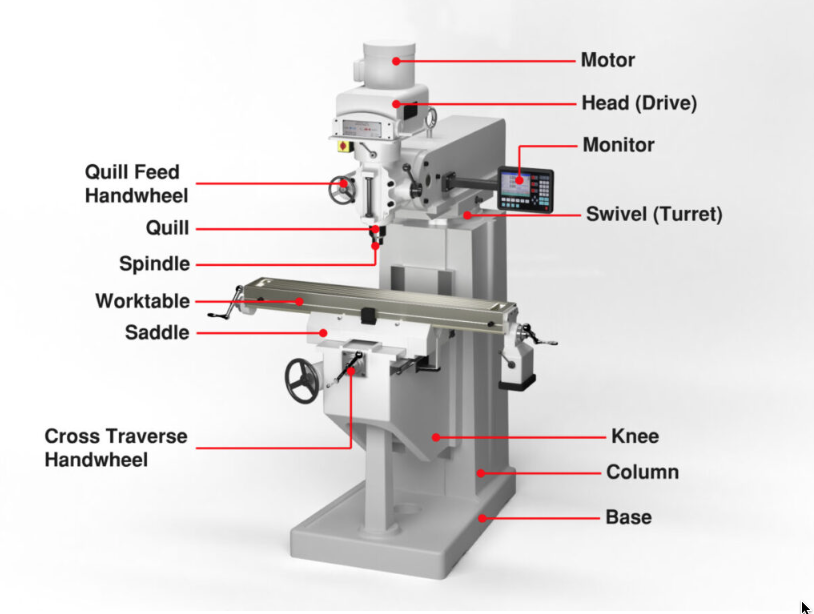

Metalworking Machines - Milling Machines

What should you know before using a milling machine?Milling machines can be dangerous if not used properly.

- Read the owner's manual carefully.

- Make sure you understand instructions and are properly trained before operating a milling machine.

What are some safe work principles to follow when using a milling machine?

- Wear appropriate CSA-certified safety glasses. Wear other personal protective equipment as necessary (such as footwear or hearing protection).

- Make sure all machines have a start/stop button within easy reach of the operator.

- Make sure that all machines have an emergency stop button (e-stop).

- Make sure that the work piece and cutter are mounted securely before taking a cut.

- Check that work is mounted squarely.

- Mount work in a vise that is bolted or held magnetically to the table. Use proper hand tools to make adjustments.

- Hold milling cutters with a cloth to avoid being cut when handling them.

- Move table as far as possible from cutter while setting up work to avoid injuring your hands.

- Mill the largest surface first.

- Keep hands, brushes and rags away from the revolving milling cutter.

- Use a vacuum, brush or rake to remove cuttings only after the cutters have stopped moving.

- Change cutting compounds periodically.

- Keep cutters sharpened correctly and in good condition.

- Keep working surface clear of scraps, tools and materials.

- Remove cutting tools from spindle when cleaning the machine.

- Keep floor around the milling machine free of oil and grease.

- Use lifting equipment when appropriate to move heavy work to or from milling machines.

- Make sure the power is off before changing cutters.

- Always stay at the machine when it is in operation.

Before starting the machine, what should you check?Before starting, make sure that:

- all guards are in place;

- work is properly secured in place;

- bolts used to hold down work clear the tooling;

- tooling and supporting pieces are properly tightened in position;

- table stops are secured properly;

- handles on all feed screws are in neutral;

- table is free of stock, tools or other loose material;

- the arbor and arbor support are clear of the work;

- the cutter is rotating in the right direction.

What should you consider when setting the cutting speed?Make sure that the following factors are considered when setting cutting speed:

- material to be machined

- type of cutter

- finish required

- depth of cut

- rigidity of machine and work piece

What are some things you should avoid doing?

- Do not wear gloves, rings, watches or loose clothing. Tie back and confine long hair.

- Do not attempt to mount, measure or adjust work until cutter is completely stopped.

- Do not use an excessively heavy cut or feed as it can cause the cutter to break. The flying pieces could cause serious injury.

- Do not reach over or near a revolving cutter. Keep hands at least 30 cm (12 in.) from a revolving cutter.

- Do not lean or rest hands on a moving table.

- Do not make any adjustments while the machine is running.

- Do not use paper shims to check the distance from the cutter to the stock.

- Do not move the operating levers without knowing what they control and what action is going to take place.

- Do not leave machine unattended while it is running.

|

|

|

|

|